ISD Introduces OneTouchDistribution, a Fully Automated and High-Accuracy Distribution System

Pallet, Case, or Split-Case OneTouchDistribution Fulfillment

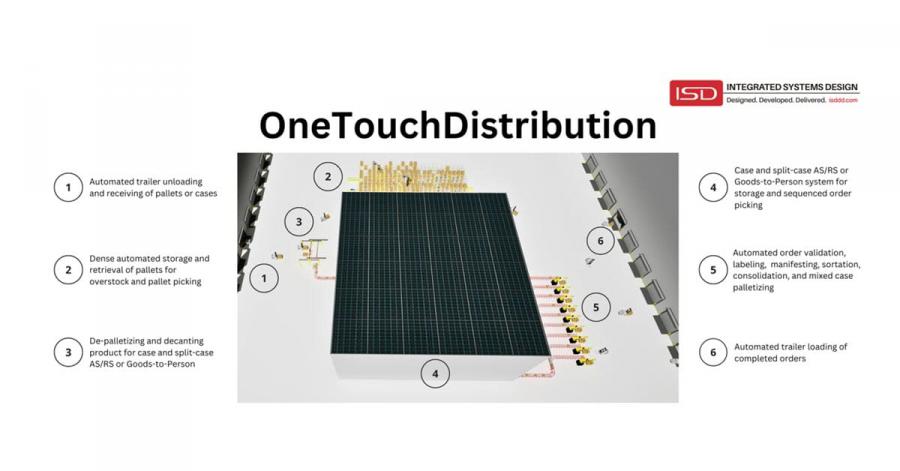

WIXOM, MI, UNITED STATES, July 16, 2025 /EINPresswire.com/ -- ISD has launched OneTouchDistribution, a cutting-edge automation system designed to optimize order fulfillment for case, split-case, and pallet operations. By integrating state-of-the-art storage, retrieval, transportation and processing technologies, the system minimizes labor requirements, enhances accuracy, and maximizes facility space utilization.

OneTouchDistribution provides a comprehensive approach to warehouse automation, offering a seamless process from inbound receipt to outbound fulfillment. The system significantly reduces labor requirements by automating receiving, storage and order processing.

By leveraging advanced tracking and sequencing, OneTouchDistribution ensures 99.9% percent pick and inventory accuracy while maintaining high throughput, even during peak demand periods. The system’s high-density design allows for the storage of hundreds of thousands of cases or split-case products in a compact footprint, making it an ideal solution for facilities looking to maximize operational efficiency without expanding their physical space.

"OneTouchDistribution was designed with flexibility and agility at its core," said Ed Romaine, VP of Marketing at ISD. "Every operation has unique challenges, and our system adapts to those needs… whether handling cases, split-cases, or pallets. It allows businesses to scale seamlessly, adjust to shifting demand, and optimize order fulfillment without disruptions. This level of adaptability ensures our clients maintain efficiency, accuracy, and speed, even in the most dynamic distribution environments."

The system automates inbound processing by receiving products through lift trucks, autonomous mobile robots, humanoids or Cobots. Once received, items are scanned, recorded, and directed into an automated storage and retrieval system that organizes and tracks each product in real time.

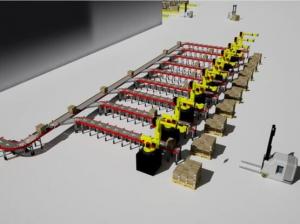

Orders are processed based on specific sequencing and fulfillment requirements, ensuring that inventory is retrieved in the optimal sequence for downstream operations. Retrieved products are sent to fully automated or semi-automated picking stations, where they are either picked and sent to a cartonizing area for split-case processing, directly routed to a sorter for case picking or delivered to palletizing and/or an outbound staging area for final shipping.

OneTouchDistribution is designed to support a wide range of industries, including food service, ecommerce, pharmaceuticals, industrial distribution, reverse logistics and third-party logistics. Its scalable architecture allows for phased implementation, enabling businesses to integrate automation at their own pace while maintaining ongoing operations.

The system’s ability to handle full-case, split-case and pallet orders within a single platform adds to its versatility, making it a viable solution for distribution centers with diverse fulfillment requirements.

The system also offers flexibility in order sequencing, allowing products to be picked and processed in a precise order based on weight, fragility, delivery requirements, order cut-off times, and customer preferences. Automated scanning and labeling ensure complete validation before orders leave the facility, reducing errors and increasing efficiency. Likewise, document printers and inserters can be easily integrated into the OneTouchDistribution system for increased revenue generation and reduced labor.

With a focus on space optimization, the system minimizes wasted storage areas and maximizes available cubic space, creating a more efficient and cost-effective distribution process.

OneTouchDistribution represents a significant advancement in warehouse automation, offering operations a high-speed, fully integrated solution that enhances productivity, improves accuracy, and reduces labor. By combining advanced automation with a scalable, adaptable design, ISD provides a solution that meets the evolving demands of modern distribution operations.

ABOUT INTEGRATED SYSTEMS DESIGN - ISD

Integrated Systems Design is a comprehensive systems integrator of automated solutions for warehouses, manufacturing, distribution, retail, and wholesale applications improving processes and productivity while reducing operational costs. Whether providing consulting services to meet current issues or developing future scalable plans to address industry challenges, ISD creates value for a broad range of industries tailoring systems to clients' specific requirements.

ISD expertise ranges from handling, storing, and picking pieces (eaches), cases, pallets, build lines, and special or custom handling solutions. Products and services include automatic storage and retrieval (ASRS), conveyor, robotics, batch stations, shuttles, pick-to-light, carousels, vertical lift modules (VLMs), controls, software (including inventory management, WCS, WMS, MES, and ERP).

Ed Romaine

Integrated Systems Design - Wixom, MI

+1 248-241-3531

email us here

Visit us on social media:

LinkedIn

Facebook

YouTube

Other

Why Select ISD as Your Systems Integrator for Warehouse and Assembly Automation Integration

Distribution channels: Automotive Industry, Beauty & Hair Care, Food & Beverage Industry, Manufacturing, Shipping, Storage & Logistics

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release